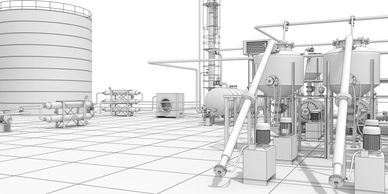

Innovative Modular Chemical Plant Solutions

Electrical & Control Design

Structural & Mechanical FEA Modeling

Structural & Mechanical FEA Modeling

We deliver fully integrated electrical and control system designs that align power distribution, instrumentation, and automation with the modular structure of your chemical plant. Each module is equipped with self-contained control cabinets, predefined electrical interfaces, and standardized communication protocols, enabling seamless interaction—whether operating autonomously or integrating with a centralized process control system (DCS or PLC-based).

Our approach ensures plug-and-play connectivity for power cables, field instrumentation, and data networks, minimizing site installation complexity while maximizing reliability and flexibility across the facility lifecycle.

- Modular Power and Instrumentation Distribution: Dedicated control cabinets per structural module, housing MCCs, low voltage transformers, and I/O panels. Power distribution is optimized for modular loads, with power and signal interfaces designed for rapid site assembly and future reconfiguration.

- Standardized Interfaces and Protocols: Clearly defined electrical and communication interconnects using industry-standard protocols (e.g., Ethernet/IP, PROFIBUS, Modbus TCP, OPC UA). This enables modules to function independently or integrate effortlessly with plant-wide control systems, supporting both distributed and centralized architectures.

- Factory-Prewired Systems: Extensive off-site wiring of panels, instruments, and junction boxes in controlled environments, with full loop checking and functional testing during FAT. Short, organized cable runs and systematic labeling practices simplify ongoing maintenance and troubleshooting.

We address the challenges of traditional field-run electrical installations, such as extended commissioning timelines, wiring errors, and the need for specialized trades during module integration or future modifications.

Partnering with us provides substantial advantages: 20-50% reduction in capital expenditure (CapEx) through minimized on-site labor and faster overall project delivery, comparable or greater savings in operating expenditure (OpEx) from reduced downtime and simplified maintenance, enhanced safety via factory-controlled installations, and true plug-and-play commissioning that dramatically shortens startup schedules. Systematic cabinet design and clear wiring practices empower process engineers to perform troubleshooting without requiring dedicated electrical specialists—lowering long-term operational costs and improving plant availability.

Streamline your chemical facility’s automation and power systems with our modular electrical and control design expertise.

Structural & Mechanical FEA Modeling

Structural & Mechanical FEA Modeling

Structural & Mechanical FEA Modeling

We provide advanced structural and mechanical modeling, including FEA, to validate and optimize modular designs under real-world loading conditions. Our analyses encompass static and dynamic load calculations in full compliance with applicable civil and structural codes, while also evaluating thermal, vibration, seismic, and piping loads on vessels, supports, and interconnected systems.

For the tall, slender structures common in distillation columns, reactors, and similar equipment, our expertise ensures robust frame design capable of withstanding the stresses of reorientation—from vertical operational positioning to horizontal transport configuration and back. This engineered flexibility enables cost-effective truck transport of large modules, while preserving structural integrity and supporting future relocation or redeployment at the end of the asset’s initial service life.

- Comprehensive Structural Load Analysis: Detailed FEA simulations covering dead loads, live loads, wind, and seismic forces per relevant codes (e.g., ASCE/AISC). Results drive optimized steel framing, baseplate design, and lifting lug configurations for safe module handling and transport.

- Multi-Physics Evaluations: Advanced modeling of thermal expansion, vibration (including pulsation and mechanical resonance), fatigue, and piping flexibility on vessels and supports. These analyses ensure long-term reliability under continuous operation and mitigate risks of stress concentrations or harmonic excitation.

We address the unique structural demands of modular chemical facilities, including the challenges of tall equipment aspect ratios and the need for designs that support asset mobility over multiple lifecycles.

Partnering with us delivers significant advantages: enhanced transportability that reduces logistics costs and expands site selection options, dramatically improved economics for pilot and demonstration-scale plants by enabling single-use assets to be relocated or repurposed rather than scrapped, and greater overall project viability through rigorous validation of structural performance before fabrication begins. This approach minimizes field modifications, accelerates commissioning, and maximizes return on investment across the full asset lifecycle.

Strengthen the foundation of your modular chemical project with our expert structural and mechanical FEA modeling.

Process and Piping Design

Structural & Mechanical FEA Modeling

Site Layouts and Interconnects

We specialize in process and piping design that bridges front-end engineering into fully integrated, modular-executable solutions. Building on robust front-end deliverables—including detailed P&IDs, control narratives, and preliminary 3D layouts—we advance into comprehensive detailed design, seamlessly integrating process equipment, piping, mechanical systems, structural elements, and instrumentation.

In contrast to conventional stick-built projects, our modular process and piping design prioritizes compact, efficient routing, standardized flanges and interconnects for rapid site assembly, and advanced 3D modeling with proactive clash detection. Hydraulic calculations, precise line sizing, and dynamic process simulations validate performance across all operating scenarios, with designs intelligently adapted to modular constraints while preserving process efficiency and reliability.

- Comprehensive P&ID Development and Integration: Detailed P&IDs with full instrumentation, control logic, and safety systems, serving as the foundation for multi-disciplinary 3D modeling that ensures accurate equipment placement, piping routes, and system interfaces.

- Modular Piping Optimization: Compact routing strategies, standardized joints, and interconnect designs that minimize field welding and alignment issues. Rigorous clash detection and 3D coordination eliminate interferences, enabling high-density layouts within transportable module envelopes.

- Performance Verification and Scalability: Advanced hydraulic analysis, line sizing, and process simulations to confirm reliable operation under varying conditions. Designs incorporate "numbering up" principles—favoring multiple parallel units over oversized equipment—to achieve exceptional turndown ratios and flexible production scaling.

We address the inherent challenges of modular chemical projects, such as space-constrained piping layouts, transport envelope restrictions, and the need for off-site hydraulic and functional validation.

Partnering with us delivers substantial value: 20-50% reductions in both capital (CapEx) and operating (OpEx) expenditures through standardization and off-site execution, significantly faster startup enabled by comprehensive factory acceptance testing (including full hydraulic verification), and superior business resilience through scalable, turndown-capable designs. In volatile markets, this modularity empowers operators to precisely match production to demand—preventing oversupply during downturns while maintaining rapid expansion potential when opportunities arise.

Optimize your chemical process with our expert process and piping design tailored for modular execution.

Site Layouts and Interconnects

Detailed 3D Modeling, Documentation, Procurement & Testing

Site Layouts and Interconnects

At Statton Engineering, we specialize in delivering cutting-edge engineering services that optimize site layouts and interconnects for chemical processing facilities. Our expertise ensures seamless on-site integration of modular systems, minimizing downtime and maximizing operational efficiency. By shifting the emphasis from off-site prefabrication to streamlined on-site assembly, we help chemical companies like yours achieve rapid deployment, regulatory compliance, and cost-effective scalability—all while navigating site-specific constraints such as brownfield expansions or proximity to feedstocks.

Our approach supports precise module placements, defined battery limits, and harmonized interactions with existing infrastructure. Whether you're extending an established plant or establishing decentralized operations, our 3D layouts provide the flexibility needed for your chemical processes. We standardize interconnects across mechanical (e.g., piping joints), fluidic, electrical, and data systems, enabling true plug-and-produce functionality that accelerates your time to market.

- Layout Optimization: We refine your site's master plan by accounting for module dimensions, weights, and installation sequences.

- Interconnect Design: Our team designs robust module-to-module connections, including structural ties, piping with expansion joints, electrical home runs, and custom connections tailored to your load and interface needs. By considering transport modes (road, rail, or barge), we factor in dynamic loads and optimize erection sequencing to safeguard your chemical assets throughout the process.

We address key challenges in the chemical industry, including spatial constraints, tight tolerances, and stringent regulations..

Partnering with us delivers transformative advantages: accelerated setup times, 30-50% reductions in on-site disruption and costs, enhanced Net Present Value (NPV) through compressed project timelines, and effortless scalability via numbering-up strategies for capacity expansions. Let our engineering services propel your chemical operations forward—contact us today to discuss how we can customize these solutions for your next project.

Safety Risk & Regulatory Compliance

Detailed 3D Modeling, Documentation, Procurement & Testing

Detailed 3D Modeling, Documentation, Procurement & Testing

We provide expert safety and regulatory design services tailored to the unique demands of chemical processing facilities. Through integration of advanced hazard analysis directly into finalized P&IDs and 3D models, we deliver robust protection for plants handling flammable, toxic, or hazardous materials—minimizing risks while accelerating project timelines and regulatory approvals.

Modular design inherently elevates safety requirements, and we excel at incorporating critical features such as integrated safety showers, comprehensive fire protection systems, and explosion-proof (Ex-rated) components that are pre-tested off-site in controlled factory environments. This proactive strategy significantly enhances operator safety, reduces on-site hazards, and supports seamless integration into your existing operations.

- HAZOP and PHA: We integrate thorough, node-based Hazard and Operability (HAZOP) studies into the P&IDs for potential deviations (e.g., no/low flow, high temperature/pressure). This process identifies and implements essential safeguards, such as interlocks and pressure safety valves (PSVs). Mid-project reviews at the 60% model stage further validate layout safety, ensuring compliant spacing and access per standards like NFPA 70E.

- Compliance Documentation: We understand comprehensive documentation packages, including HAZID, Quantitative Risk Assessment (QRA), and hazardous area zoning. Leverage our 3D modeling and other tools, we can support process safety experts in certifying compliance

Partnering with us yields substantial advantages: proactive hazard mitigation (e.g., up to 40% reductions in emissions), faster regulatory approvals through thorough upfront documentation, and markedly improved operator safety. These outcomes translate to lower lifecycle risks, reduced insurance premiums, and greater operational confidence.

Elevate the safety and compliance of your chemical operations with our specialized engineering expertise—contact us today to learn how we can integrate these critical services into your next modular project.

Detailed 3D Modeling, Documentation, Procurement & Testing

Detailed 3D Modeling, Documentation, Procurement & Testing

Detailed 3D Modeling, Documentation, Procurement & Testing

We deliver fully integrated 3D modeling and comprehensive engineering deliverables that unify all disciplines throughout the project lifecycle. Leveraging advanced tools like Navisworks, we conduct structured 30%, 60%, and 90% model reviews to ensure clash-free designs and early issue resolution. This disciplined approach generates precise fabrication-ready packages—including isometrics, bills of materials (BOMs), and spool drawings—while enabling concurrent procurement of long-lead items such as pressure vessels.

Vendor data is seamlessly incorporated post-HAZOP, and rigorous Factory Acceptance Testing (FAT) and Site Acceptance Testing (SAT) protocols—including hydrostatic and pneumatic pressure tests, instrument loop checks, and functional simulations—can be executed off-site to achieve 80-90% mechanical completion before modules leave the factory. This maximizes quality control, minimizes field rework, and accelerates overall project schedules.

We address key challenges in modular chemical projects, including management of tight fabrication tolerances, and coordination of overlapping disciplines (e.g., process piping interfacing with structural steel) from the FEED stage onward.

Partnering with us delivers measurable advantages: 30-50% compression in overall project schedules through concurrent engineering and off-site completion, single-source accountability that reduces change orders and disputes, and significant net present value (NPV) gains from earlier plant startup and revenue generation. The integrated approach also minimizes on-site labor requirements, enhances constructability, and ensures seamless module integration at the final site.

Accelerate your modular chemical project with our proven integrated modeling and deliverables expertise.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.