Front End Engineering Design

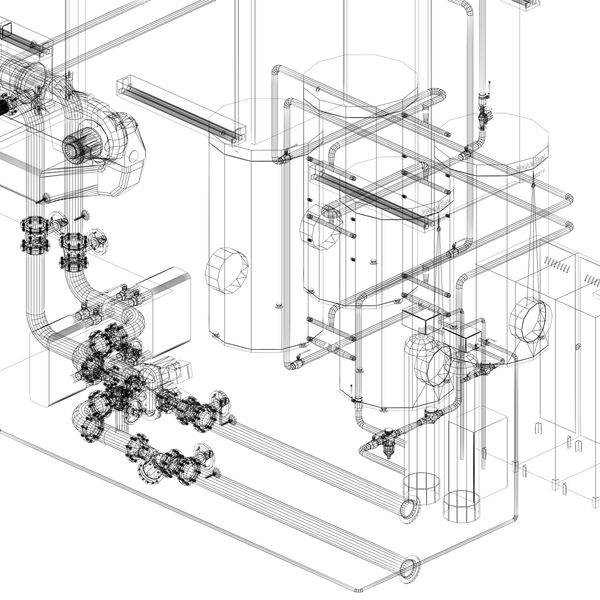

At Statton Engineering, we partner closely with each client to deliver tailored Front-End Engineering Design (FEED) packages that transform your chemical process concept into a fully defined, investment-ready solution. Our FEED process bridges early ideation to executable construction, producing a comprehensive basic engineering package with cost certainty typically ranging from ±15% to as tight as ±5%, depending on your specific requirements.

This critical phase establishes the technical foundation and modularization strategy that enables accurate construction proposals, streamlined procurement, and seamless transition into detailed design and fabrication—while unlocking the full schedule and cost advantages of modular execution.

- Design Basis and Process Development: Collaborative establishment of process and project design basis, including operational reviews, safety assessments, and progression from process flow diagrams (PFDs) to detailed piping and instrumentation diagrams (P&IDs).

- Equipment and Interface Definition: Specification of long- and medium-lead items to procurement-ready levels, preliminary line sizing, piping class selection, primary electrical load estimates, and clear definition of inter-module interfaces for piping, electrical, instrumentation, and utilities.

- Modular Layout and Strategy: Development of modularization approaches optimized for highway transport or containerized shipping, preliminary module sizing for structural design, 3D model-based site layouts, and plot plans that facilitate early engagement with site development contractors.

- Cost, Schedule, and Deliverables: Class 1 capital cost estimate (±15/-3%) with detailed breakdowns, Level 4/5 construction schedules incorporating modular fabrication timelines, control philosophy, I/O summaries, equipment/instrument/valve lists, datasheets, line lists, fluid service descriptions, and value engineering reviews.

Core Activities and Deliverables

We facilitate structured workshops and reviews—including kickoff meetings, P&ID development sessions, and HAZOP participation as process experts—to ensure alignment and risk mitigation. Key outputs include:

- Fully annotated P&IDs with multiple client review cycles

- Comprehensive equipment, instrument, and valve lists and datasheets

- Preliminary 3D models for layout visualization and contractor coordination

- Engineering calculations supporting hydraulics, electrical loads, and overall project basis

- Modularization strategy, plot plans, and conceptual structural framing

- Detailed construction cost proposal and high-level project schedule

Proven Benefits and Critical Considerations

By embedding modular principles early in FEED, we address the limitations of traditional stick-built planning—such as extended timelines, field coordination risks, and cost overruns—while maximizing off-site execution advantages.

Clients achieve dramatic results: overall project schedules shortened by up to 12 months compared to equivalent stick-built facilities, 10-30% total installed cost reductions through optimized procurement, factory testing, and reduced site labor, and greater investment certainty from robust early definition and de-risked modular strategies.

De-risk and accelerate your chemical project with our expert Front-End Engineering Design services. Contact us today to learn how a modular-focused FEED can deliver superior speed, cost savings, and execution confidence for your next facility.

This website uses cookies.

We use cookies to analyze website traffic and optimize your website experience. By accepting our use of cookies, your data will be aggregated with all other user data.